The effect of elevated temperature on viral viability is clear: after one week at 37°C in a buffered solution, adenovirus vaccine vectors lose all infectivity and cannot stimulate immune responses. Poxvirus vaccine vectors endure up to 1 month at 37°C or 45°C but then lose effectiveness.

An important component of the new vaccine preservation technique is the ability of the non-reducing disaccharides trehalose and sucrose to form a solid in which no chemical reactions occur. Because of this property, these sugars are often used as stabilizing agents for biological products.

Adenovirions and poxvirions were placed in suspensions of a mixture of trehalose and sucrose and slowly dried onto filters at ambient temperatures. The sugars formed an ultrathin glass on the membrane in which the virions were suspended. In this form the viruses could be stored for up to 6 months at 45°C with no loss of infectivity of immunogenicity.

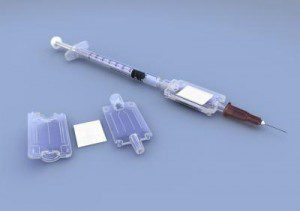

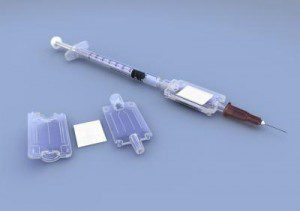

The ability to preserve viral vaccines on a small filter also allows simple administration of the vaccine. The virus-containing filter is placed into a plastic holder which can be fitted between a conventional syringe and needle. As buffer is forced through the filter, the vaccine-containing glass dissolves and flows into the needle for injection.

There are many questions that must be answered before this technology can be put into general use. It remains to be determined whether glass-embedded vaccines will be stable when subjected to extreme temperature fluctuations encountered during shipment. Furthermore, the method of preservation must be shown to work for currently used vaccines, such as those for polio.

The oral poliovaccine was once given to children on cubes of sugar. Embedding viruses in sugar may soon allow less costly and more effective global delivery of disease-preventing vaccines.

Alcock, R., Cottingham, M., Rollier, C., Furze, J., De Costa, S., Hanlon, M., Spencer, A., Honeycutt, J., Wyllie, D., Gilbert, S., Bregu, M., & Hill, A. (2010). Long-Term Thermostabilization of Live Poxviral and Adenoviral Vaccine Vectors at Supraphysiological Temperatures in Carbohydrate Glass Science Translational Medicine, 2 (19), 19-19 DOI: 10.1126/scitranslmed.3000490

This is my first time i visit here. I found so many interesting stuff in your blog especially its discussion. I guess I am not the only one having all the enjoyment here! keep up the good work.

The cold chain VS temperature controller